I never herd of no 'fiber wool jelly' batteria

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

LOL TRUCK

- Thread starter Cole of Them Northwoods

- Start date

No need for custom wiring jobs. They make solid state flasher modules that are plug and playJohnny- you hav probably thot about replacing turn signales with LEDs already

You mentioned prolonged turn signal use. I often hav need of leaving hazard flashers blinking while working near traffuck, so hav wired up dedicated LED strobe circuits on my trucks. There are cheapo-chiner strobe systems available using 1w or 3w LEDs, you mite wanna consider.

I like using the 3w chiner LEDs in conjuction with FENIEX flasher-controller https://www.feniex.com/controllers/4x-flasher

I dont like the incandescent bulbs, they draw a lotta electrons and LEDs are cheap now.

Some vehicles made after 1990 that came with incandescent brake lites run low voltage thru the brakelite circuit as part of the transmission lockup but obv thats not something u need to deal with on the Ape

Gawn Chippin

Arachnocronymic Metaphoron

...LEDs are cheap now...

Cheap in both quality and price. As soon as I can obtain Japanese versions, I'll snapp up on them, even if the price isn't right

85 cc single cylinder engine? That seems pretty underpowered...How many gears does it hav in transmission?...

The transmission is geared down like a tractor. Otherwise, I wouldn't be able to make it up steep inclines with heavy loads.

Some owners switch the primary gear (pointed to by the yellow arrow) accordingly, for the purpose of obtaining a higher top speed. You would think that adding a tooth more to a primary gear while keeping the secondary one as is to be defying the law of physics. But nevertheless, it somehow wörks. As soon as they do this though, at this point trouble could begin, when insurance adjusters discover this tweakery, in the event of an accident.

The lavender-colored arrow points to the reverse gear mechanism with its retaining spring:

Shown here is a speedometer drive of which can't spy on me, as well as the oil injector pump when hooked up:

Some owners switch the primary gear (pointed to by the yellow arrow) accordingly, for the purpose of obtaining a higher top speed. You would think that adding a tooth more to a primary gear while keeping the secondary one as is to be defying the law of physics. But nevertheless, it somehow wörks.

Involute gears have the same teeth between a given tooth-count range. For instance, all involute gears (for a given DP/module) between say 8-12 teeth will share the same tooth profile. If swapping that pinion/primary for another one with +1 teeth, it probably has the same exact tooth profile as the one it replaced. But even if the replacement pinion goes 'out of range' due to different number of teeth than the original, it's just made with a different profile that keeps the proper mesh. The big ring/secondary gear tho, its gonna have a different profile than the pinion.

Helpfull vidja: (jump to 9:00)

Gawn Chippin

Arachnocronymic Metaphoron

This is what a set of these look like:

www.casa-moto-shop.de

www.casa-moto-shop.de

An original 14-tooth replacement:

I started bolting everything back together, keeping the old gasket, degreasing it with brake cleaner spray and using sillycoon as a sealer. I snugged the cover, overnight, expecting the silicone to get somewhat firm, before final tightening. I don't know if cold temperature is preventing the silicone from hardening. I don't recall ever having had these problems. Perhaps, this silicone tube might happen to be too old?

Casa Moto | Getriebeübersetzung 4.25 schrägverzahnt Z=16/68 für Ape 50 | Casa Moto Shop

Getriebeübersetzung 4.25 schrägverzahnt Z=16/68 für Ape 50 - Getriebeübersetzung komplett mit Primärritzel 16 Zähne und Großes Zahnrad mit 68 Zähne. Übersetzung 4.25. Ideal für Zylindersätze von 85ccm

Gear ratio complete with primary pinion 16 teeth and large gear with 68 teeth. Reduction ratio: 4.25:1

Ideal for cylinder sets ranging from 85cc to 115cc. Slightly longer ratio than original, helical teeth suitable for all Ape 50 models. For higher top speed depending on the cylinder.

An original 14-tooth replacement:

Primärzahnrad 14 Zähne "Piaggio" Vespa PK, Ape | eBay

Primärzahnrad 14 Zähne "Piaggio" Vespa PK, Ape Piaggio code: 2452374. Primärzahnrad 25 Zähne für 69 Zähne Primär "Cri. 65,33 EUR. Primärzahnrad 26 Zähne für 69 Zähne Primär "Cri. 65,33 EUR. Primärzahnrad 27 Zähne für 69 Zähne Primär "Cri. 65,33 EUR.

www.ebay.co.uk

I started bolting everything back together, keeping the old gasket, degreasing it with brake cleaner spray and using sillycoon as a sealer. I snugged the cover, overnight, expecting the silicone to get somewhat firm, before final tightening. I don't know if cold temperature is preventing the silicone from hardening. I don't recall ever having had these problems. Perhaps, this silicone tube might happen to be too old?

Last edited:

Gawn Chippin

Arachnocronymic Metaphoron

I buttoned up this maintenance, enuff to where I can start driving this again. The factory braces of which were meant to serve as back-up braces in case of engine mount failure has been replaced through a cable system. The brace can be seen, in the following image, located to the right of the yellow encirclement:

This system has been replaced by the following. Since having installed the external fuel filter, this amount of water has been trapped. Others who do not perform this modification report having problems. Because this is a gravity feed system, the failure to sever the fuel screen located in the carburetor inlet will prevent fuel flow.

Because of the rise in fuel prices, speculating on refuelling during price slumps , I have avoided keeping a full tank of which would have prevented the accumulation of excessive moisture condensation. After having removed this accumulated water, more seeped in, after having opened the tank's fuel valve, meaning that I will once again drain the filter at least once:

, I have avoided keeping a full tank of which would have prevented the accumulation of excessive moisture condensation. After having removed this accumulated water, more seeped in, after having opened the tank's fuel valve, meaning that I will once again drain the filter at least once:

Both double-eyelet cables have been connected with a shortened brake cable harvested from a bicycle, using a sawed-off automotive valve stem made of brass(?). A set of electrician's crimp pliers was used for crimping:

This system has been replaced by the following. Since having installed the external fuel filter, this amount of water has been trapped. Others who do not perform this modification report having problems. Because this is a gravity feed system, the failure to sever the fuel screen located in the carburetor inlet will prevent fuel flow.

Because of the rise in fuel prices, speculating on refuelling during price slumps

, I have avoided keeping a full tank of which would have prevented the accumulation of excessive moisture condensation. After having removed this accumulated water, more seeped in, after having opened the tank's fuel valve, meaning that I will once again drain the filter at least once:

, I have avoided keeping a full tank of which would have prevented the accumulation of excessive moisture condensation. After having removed this accumulated water, more seeped in, after having opened the tank's fuel valve, meaning that I will once again drain the filter at least once:

Both double-eyelet cables have been connected with a shortened brake cable harvested from a bicycle, using a sawed-off automotive valve stem made of brass(?). A set of electrician's crimp pliers was used for crimping:

Last edited:

Gawn Chippin

Arachnocronymic Metaphoron

If only I could get Japanese LEDs, I would. That smaller motorcycle battery gets drained quicker, ever since I replaced my original 10 watt signal bulbs with 21 watters. Yellow Peril crappola isn't getting anywhere near my stuff...you hav probably thot about replacing turn signales with LEDs already...

Gawn Chippin

Arachnocronymic Metaphoron

Beware of jogger-hating bears. The following is about to pay the death penalty for being hungry:...I've only ever seen these things in mountainous areas of italy...

Jogger (26) von einem Bären zerfleischt – Autopsie bestätigt es

In der norditalienischen Provinz Trient unweit der Schweizer Grenze hat ein Bär einen Jogger tödlich verletzt. Am Freitag wurden die Ergebnisse der Autopsie an der Leiche veröffentlicht.

How to blend your own synthetic oil:

If the Three Stooges would have taken up automotive mechanics instead of Slapschtik Comedy:

Gawn Chippin

Arachnocronymic Metaphoron

Gawn Chippin

Arachnocronymic Metaphoron

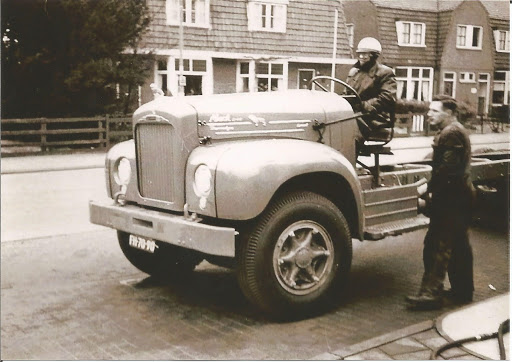

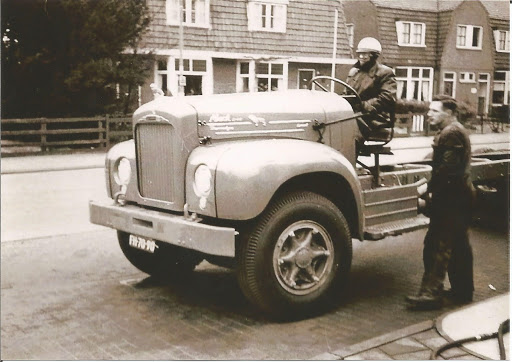

What ever happened to Mack tracks?

Gawn Chippin

Arachnocronymic Metaphoron

1 Ape vs. 2 4-wheelers. Guess whoo wunn...The ape is dangerous very easy to flip over,...